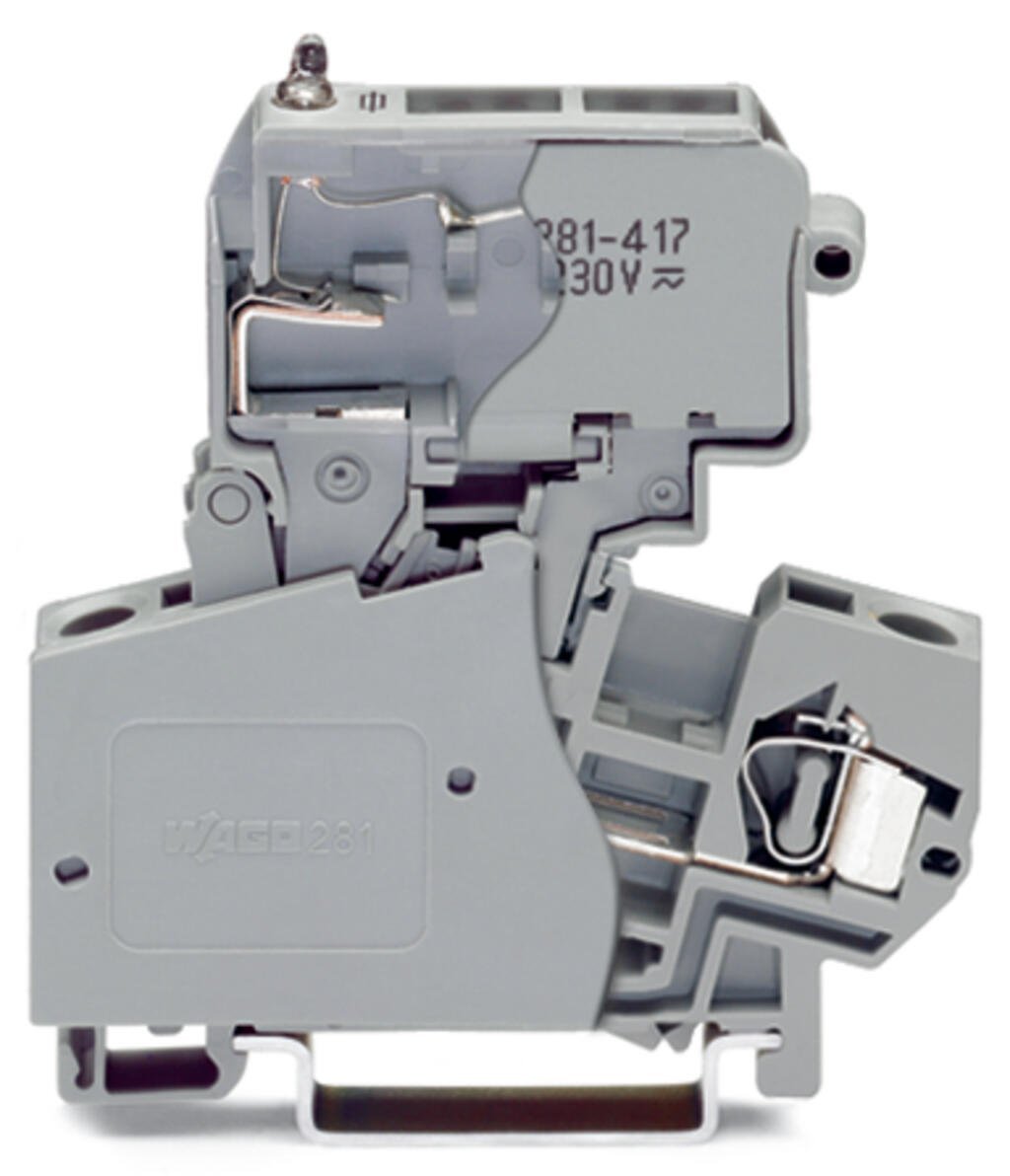

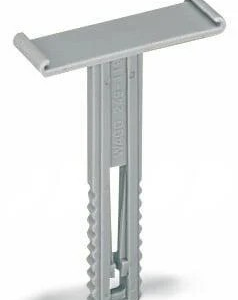

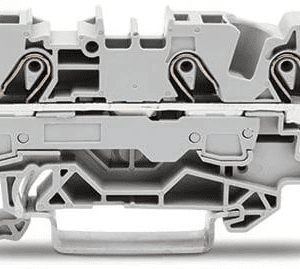

Cầu đấu dây 281-623/281-418 2-conductor fuse terminal block

Item no. 281-623/281-418

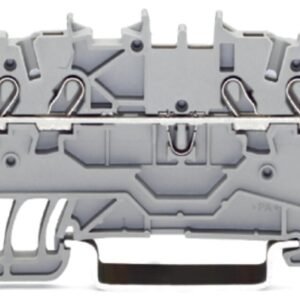

2-conductor fuse terminal block

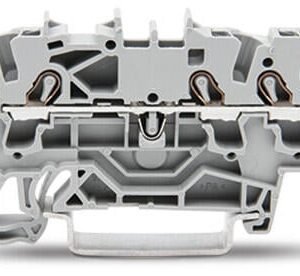

2-conductor fuse terminal block; with pivoting fuse holder; for glass cartridge fuse ¼” x 1¼”; with blown fuse indication by neon lamp; 120 V; for DIN-rail 35 x 15 and 35 x 7.5; 4 mm²; CAGE CLAMP®; 4,00 mm²; gray

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

2-conductor fuse terminal block; with pivoting fuse holder; for glass cartridge fuse ¼” x 1¼”; with blown fuse indication by neon lamp; 120 V; for DIN-rail 35 x 15 and 35 x 7.5; 4 mm²; CAGE CLAMP®; 4,00 mm²; gray

Item no. 281-623/281-418

2-conductor fuse terminal block

281-623/281-418

Electrical data

Ratings per IEC/EN

Ratings per IEC/EN – Notes

| Ratings (note) | Electrical ratings are given by the fuse and blown fuse indication. |

| Rated current (note) | Leakage current in case of a blown fuse: Neon lamp < 0.4 mA |

281-623/281-418

Power Loss

| Power loss (max.) Pl (max.) (note) | When selecting glass cartridge fuses, make sure that the maximum power loss listed below is not exceeded. The power loss is determined according to IEC or EN 60947-7-3/VDE 0611-6 at 23°C. The temperature rise of the terminal block must be checked according to their application and mounting. Higher ambient temperatures represent an additional impact on miniature fuses. Therefore, in such applications, the rated current must be reduced if necessary. More details are available from the manufacturers. |

| Power loss Pl max. overload and short-circuit protection (individual arrangement) | 2.5W |

| Power loss Pl max. overload and short-circuit protection (group arrangement) | 1.6W |

| Power loss Pl max. short-circuit protection (individual arrangement) | 4W |

| Power loss Pl max. short-circuit protection (group arrangement) | 2.5W |

General information

| Fuse receptacle | pivoting |

| Fuse type | Cylindrical fuse; ¼” x 1¼” |

Connection data

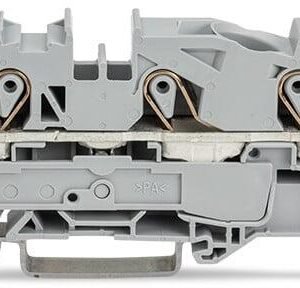

| Clamping units | 2 |

| Total number of potentials | 2 |

| Number of levels | 1 |

281-623/281-418

Connection 1

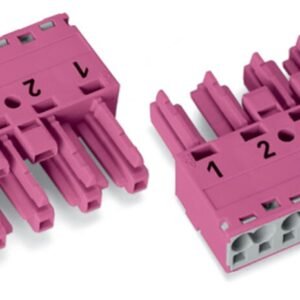

| Connection technology | CAGE CLAMP® |

| Actuation type | Operating tool |

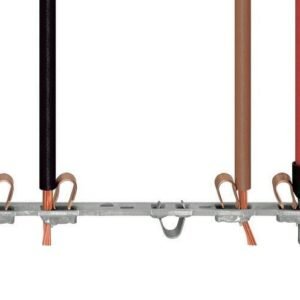

| Connectable conductor materials | Copper Aluminum |

| Connectable conductor materials (note) | Terminating Aluminum Conductors WAGO Spring-Clamp Terminal Blocks are suitable for solid aluminum conductors up to 4 mm²/12 AWG if WAGO “Alu-Plus” Contact Paste 249-130 is used for termination.“Alu-Plus” Contact Paste Advantages:

Using terminal blocks with CAGE CLAMP® Spring Pressure Connection Technology, aluminum conductors must first be cleaned with a blade and then immediately inserted into the clamping units filled with “Alu-Plus” contact paste. It is also possible to apply WAGO “Alu-Plus” additionally on the whole surface of the aluminum conductor before termination. Please note that the nominal currents must be adapted to the reduced conductivity of the aluminum conductors: |

| Solid conductor | 0.08 … 4 mm² / 28 … 12 AWG |

| Fine-stranded conductor | 0.08 … 4 mm² / 28 … 12 AWG |

| Strip length | 9 … 10 mm / 0.35 … 0.39 inches |

| Wiring direction | Front-entry wiring |

Physical data

| Width | 10 mm / 0.394 inches |

| Height | 60 mm / 2.362 inches |

| Depth from upper-edge of DIN-rail | 60 mm / 2.362 inches |

Mechanical data

| Design | angled |

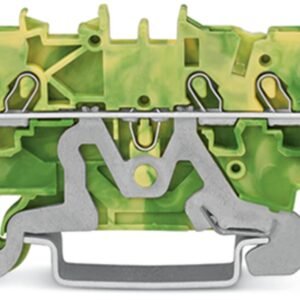

| Mounting type | DIN-35 rail |

| Marking level | Center marking |

Material data

| Note (material data) | Information on material specifications can be found here |

| Color | gray |

| Material group | I |

| Insulation material (main housing) | Polyamide (PA66) |

| Flammability class per UL94 | V0 |

| Fire load | 0.382MJ |

| Weight | 19.8g |

Sản phẩm tương tự

Rail-Mount Terminal Blocks

Rail-Mount Terminal Blocks

Rail-Mount Terminal Blocks

Cầu Đấu Dây

Rail-Mount Terminal Blocks

Cầu Đấu Dây

Rail-Mount Terminal Blocks

Bộ Điều Khiển PLC

Cầu Đấu Dây

Rail-Mount Terminal Blocks

Cầu Đấu Dây