750-833 | WAGO | Controller PROFIBUS Slave

WAGO – 750-833

Controller PROFIBUS Slave

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

SKU: 750-833

Danh mục: Bộ Điều Khiển PLC, WAGO

Thẻ: 750-833, 750-833 wago, bộ điều khiển 750-833, bộ điều khiển PLC WAGO, phân phối wago việt nam, PLC WAGO, slave 750-833, slave wago 750-833, terminal wago, wago, wago 750-833, wago tại việt nam

Thương hiệu: WAGO

4.9/5 - (866 bình chọn)

750-833

Technical data

| Communication | PROFIBUS |

| Visualization | none |

| CPU | 16 bits |

| Programming languages per IEC 61131-3 | Instruction List (IL) Ladder Diagram (LD) Function Block Diagram (FBD) Continuous Function Chart (CFC) Structured Text (ST) Sequential Function Chart (SFC) |

| Programming environment | WAGO-I/O-PRO V2.3 (based on CODESYS V2.3) |

| Configuration options | GSD device description file WAGO-I/O-CHECK |

| Cycle time | < 3 ms for 1000 bit instructions/ 256 digital I/O |

| Baud rate (communication/fieldbus 1) | 9.6/12 MBd |

| Baud rate | 9.6/12 MBd |

| Bus segment length (max.) | 1200 m |

| Transmission medium (communication/fieldbus) | Cu cable per EN 50170 |

| Transmission time | typ. 1 ms (10 controllers; each 32 digital I/O and 12 Mbaud) max. 3.3 ms |

| Number of fieldbus nodes on master (max.) | 96 |

| Number of I/O points | 6,000 |

| Program memory | 128 KB |

| Data memory | 64 KB |

| Non-volatile software memory | 8kbyte |

| Memory for fieldbus input variables (max.) | 244Byte |

| Memory for fieldbus output variables (max.) | 244Byte |

| Number of modules per node (max.) | 63 |

| Number of modules without a bus extension (max.) | 63 |

| Input and output process image (fieldbus) max. | 244 bytes/244 bytes |

| Indicators | LED (RUN) green: Fieldbus initialization, LED (BF, DIA, BUS) red: communication error, external diagnostics, configuration; LED (I/O, USR) red/green/orange: Local data bus status, status programmable by user; LED (A, B) green: System power supply status, field supply |

| Supply voltage (system) | 24 VDC (-25 … +30 %); via pluggable connector (CAGE CLAMP® connection) |

| Input current (typ.) at nominal load (24 V) | 500mA |

| Power supply efficiency (typ.) at nominal load (24 V) | 87% |

| Current consumption (5 V system supply) | 200mA |

| Total current (system supply) | 1,800mA |

| Supply voltage (field) | 24 VDC (-25 … +30 %); via power jumper contacts |

| Current carrying capacity (power jumper contacts) | 10A |

| Number of outgoing power jumper contacts | 3 |

| Isolation | 500 V system/field |

| Standard | EN 50170 |

Connection data

750-833

| Connection technology: communication/fieldbus | PROFIBUS: 1 x D-Sub 9 socket |

| Connection technology: system supply | 2 x CAGE CLAMP® |

| Connection technology: field supply | 6 x CAGE CLAMP® |

| Connection type 1 | System/field supply |

| Solid conductor | 0.08 … 2.5 mm² / 28 … 14 AWG |

| Fine-stranded conductor | 0.08 … 2.5 mm² / 28 … 14 AWG |

| Strip length | 8 … 9 mm / 0.31 … 0.35 inches |

| Connection technology: device configuration | 1 x Male connector; 4-pole |

Physical data

| Width | 50.5 mm / 1.988 inches |

| Height | 100 mm / 3.937 inches |

| Depth | 71.1 mm / 2.799 inches |

| Depth from upper-edge of DIN-rail | 63.9 mm / 2.516 inches |

Mechanical data

750-833

| Weight | 186.9g |

| Color | light gray |

| Housing material | Polycarbonate; polyamide 6.6 |

| Conformity marking | CE |

Environmental requirements

| Ambient temperature (operation) | 0 … +55 °C |

| Ambient temperature (storage) | -25 … +85 °C |

| Protection type | IP20 |

| Pollution degree | 2 per IEC 61131-2 |

| Operating altitude | without temperature derating: 0 … 2000 m; with temperature derating: 2000 … 5000 m (0.5 K/100 m); 5000 m (max.) |

| Relative humidity (without condensation) | 95% |

| Mounting position | Horizontal left, horizontal right, horizontal up, horizontal down, vertical top and vertical bottom |

| Mounting type | DIN-35 rail |

| Vibration resistance | 4g per IEC 60068-2-6 |

| Shock resistance | 15g per IEC 60068-2-27 |

| EMC immunity to interference | per EN 61000-6-2, marine applications |

| EMC emission of interference | per EN 61000-6-4, marine applications |

| Exposure to pollutants | Per IEC 60068-2-42 and IEC 60068-2-43 |

| Fire load | 3.002MJ |

| Permissible H2S contaminant concentration at a relative humidity 75 % | 10ppm |

| Permissible SO2 contaminant concentration at a relative humidity 75 % | 25ppm |

Sản phẩm tương tự

Cầu Đấu Dây

Cầu Đấu Dây

Hệ Thống I/O

Cầu Đấu Dây

Cầu Đấu Dây

Hệ Thống I/O

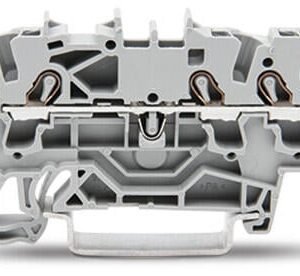

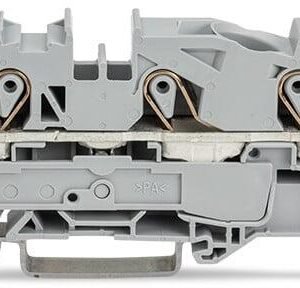

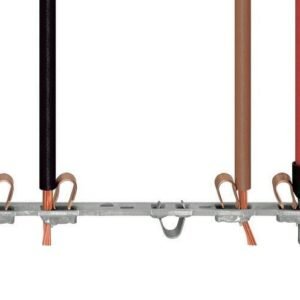

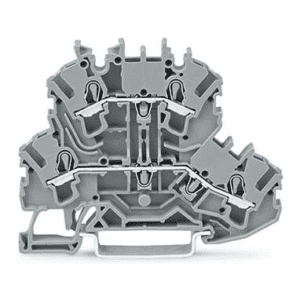

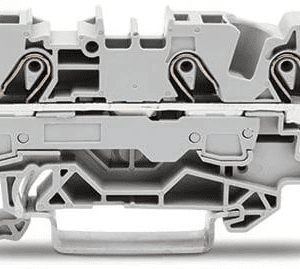

Rail-Mount Terminal Blocks

Item no. 2202-1301/000-001 3-conductor through terminal block

Bộ Điều Khiển PLC

Cầu Đấu Dây

Hệ Thống I/O

Cầu Đấu Dây