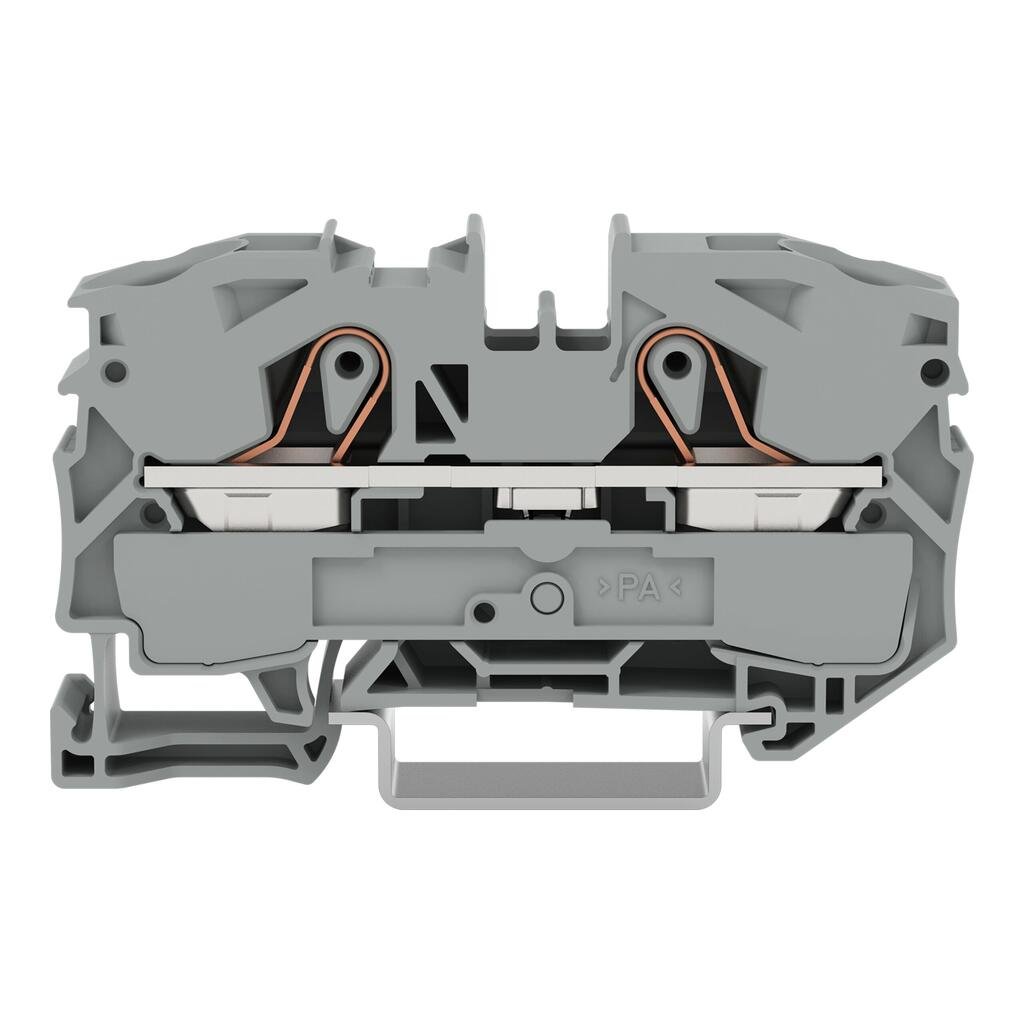

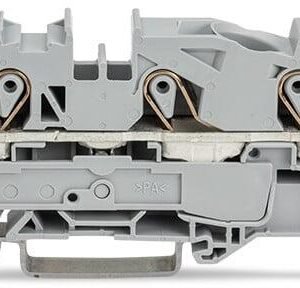

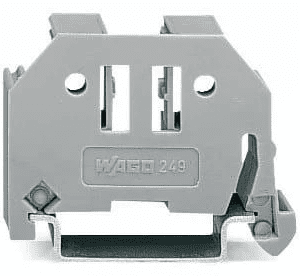

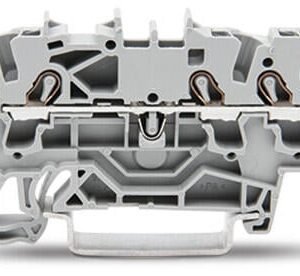

2016-1201 2-conductor through terminal block

2016-1201

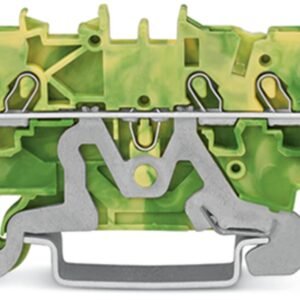

2-conductor through terminal block; 16 mm²; suitable for Ex e II applications; side and center marking; for DIN-rail 35 x 15 and 35 x 7.5; Push-in CAGE CLAMP®; 16,00 mm²; gray

-

sản phẩm chính hãng, MỚI 100% CHƯA SỬ DỤNG

-

SẢN PHẨM LUÔN ĐƯỢC KIỂM TRA TRƯỚC KHI XUẤT KHO

-

BẢO HÀNH 12 THÁNG ĐỐI VỚI LỖI CỦA NHÀ SẢN XUẤT / HOẶC THEO CHÍNH SÁCH CỦA SẢN PHẨM DO TRƯỜNG THỊNH PHÂN PHỐI

-

HỖ TRỢ KỸ THUẬT 24/7

-

MIỄN PHÍ GIAO HÀNG ĐỐI VỚI CÁC ĐƠN HÀNG TỪ 8,000,000VNĐ

Liên hệ:

SKU: 2016-1201

Danh mục: Rail-Mount Terminal Blocks

Thẻ: 2016-1201, 2016-1201 wago, đại lý wago, phân phối wago việt nam, wago, wago 2016-1201, wago hcm, wago ho chi minh, wago sai gon, wago việt nam, wago vung tau

Thương hiệu: WAGO

4.9/5 - (866 bình chọn)

2-conductor through terminal block; 16 mm²; suitable for Ex e II applications; side and center marking; for DIN-rail 35 x 15 and 35 x 7.5; Push-in CAGE CLAMP®; 16,00 mm²; gray

2016-1201

Ex information

| Reference hazardous areas | See application instructions in section “Knowledge and Downloads – Documentation – Additional Information: Technical Section; Technical Explications” |

| Ratings per | ATEX: PTB 05 ATEX 1031 U / IECEx: PTB 05.0015U (Ex eb IIC Gb) |

| Rated voltage EN (Ex e II) | 550V |

| Rated current (Ex e II) | 70A |

| Rated current (Ex e II) with jumper | 67A |

Power Loss

| Power loss, per pole (potential) | 2.426W |

| Rated current IN for specified power loss | 76A |

| Resistance value for specified, current-dependent power loss | 0Ω |

Connection

| Connection technology | Push-in CAGE CLAMP® |

| Actuation type | Operating tool |

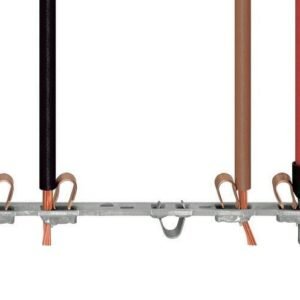

| Connectable conductor materials | Copper |

| Nominal cross-section | 16 mm² |

| Solid conductor | 0.5 … 16 mm² / 20 … 6 AWG |

| Solid conductor; push-in termination | 6 … 16 mm² / 14 … 6 AWG |

| Fine-stranded conductor | 0.5 … 25 mm² / 20 … 4 AWG |

| Fine-stranded conductor; with insulated ferrule | 0.5 … 16 mm² / 20 … 6 AWG |

| Fine-stranded conductor; with ferrule; push-in termination | 6 … 16 mm² / 10 … 6 AWG |

| Note (conductor cross-section) | Depending on the conductor characteristic, a conductor with a smaller cross-section can also be inserted via push-in termination. AWG specifications were converted according to IEC. |

| Strip length | 18 … 20 mm / 0.71 … 0.79 inches |

| Wiring direction | Front-entry wiring |

Physical data

| Width | 12 mm / 0.472 inches |

| Height | 69.8 mm / 2.748 inches |

| Depth from upper-edge of DIN-rail | 36.9 mm / 1.453 inches |

| Depth | 43.5 mm / 1.713 inches |

Environmental Testing (Environmental Conditions)

| Test specification Railway applications – Rolling stock – Electronic equipment |

DIN EN 50155 (VDE 0115-200):2022-06 |

| Test procedure Railway applications – Rolling stock equipment – Shock and vibration tests |

DIN EN 61373 (VDE 0115-0106):2011-04 |

| Spectrum/Installation location | Service life test, Category 1, Class A/B |

| Function test with noise-like vibration | Test passed according to Section 8 of the standard |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| Acceleration | 0.101g (highest test level used for all axes) |

| Test duration per axis | 10 min. |

| Test directions | X, Y and Z axes |

| Monitoring for contact faults/interruptions | Passed |

| Voltage drop measurement before and after each axis | Passed |

| Simulated service life test through increased levels of noise-like vibration | Test passed according to Section 9 of the standard |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| Acceleration | 0.572g (highest test level used for all axes) |

| Test duration per axis | 5 h |

| Test directions | X, Y and Z axes |

| Extended test scope: Monitoring for contact faults/interruptions | Passed |

| Extended test scope: Voltage drop measurement before and after each axis | Passed |

| Shock test | Test passed according to Section 10 of the standard |

| Shock form | Half sine |

| Acceleration | 5g (highest test level used for all axes) |

| Shock duration | 30 ms |

| Number of shocks per axis | 3 pos. und 3 neg. |

| Test directions | X, Y and Z axes |

| Extended test scope: Monitoring for contact faults/interruptions | Passed |

| Extended test scope: Voltage drop measurement before and after each axis | Passed |

| Vibration and shock stress for rolling stock equipment | Passed |

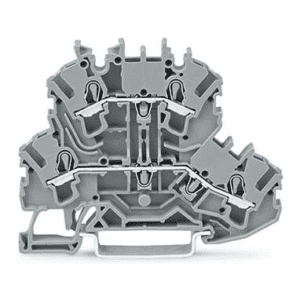

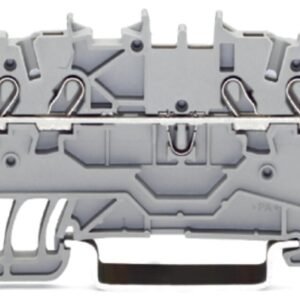

Sản phẩm tương tự

Rail-Mount Terminal Blocks

Rail-Mount Terminal Blocks

Item no. 2202-1301/000-001 3-conductor through terminal block

Rail-Mount Terminal Blocks

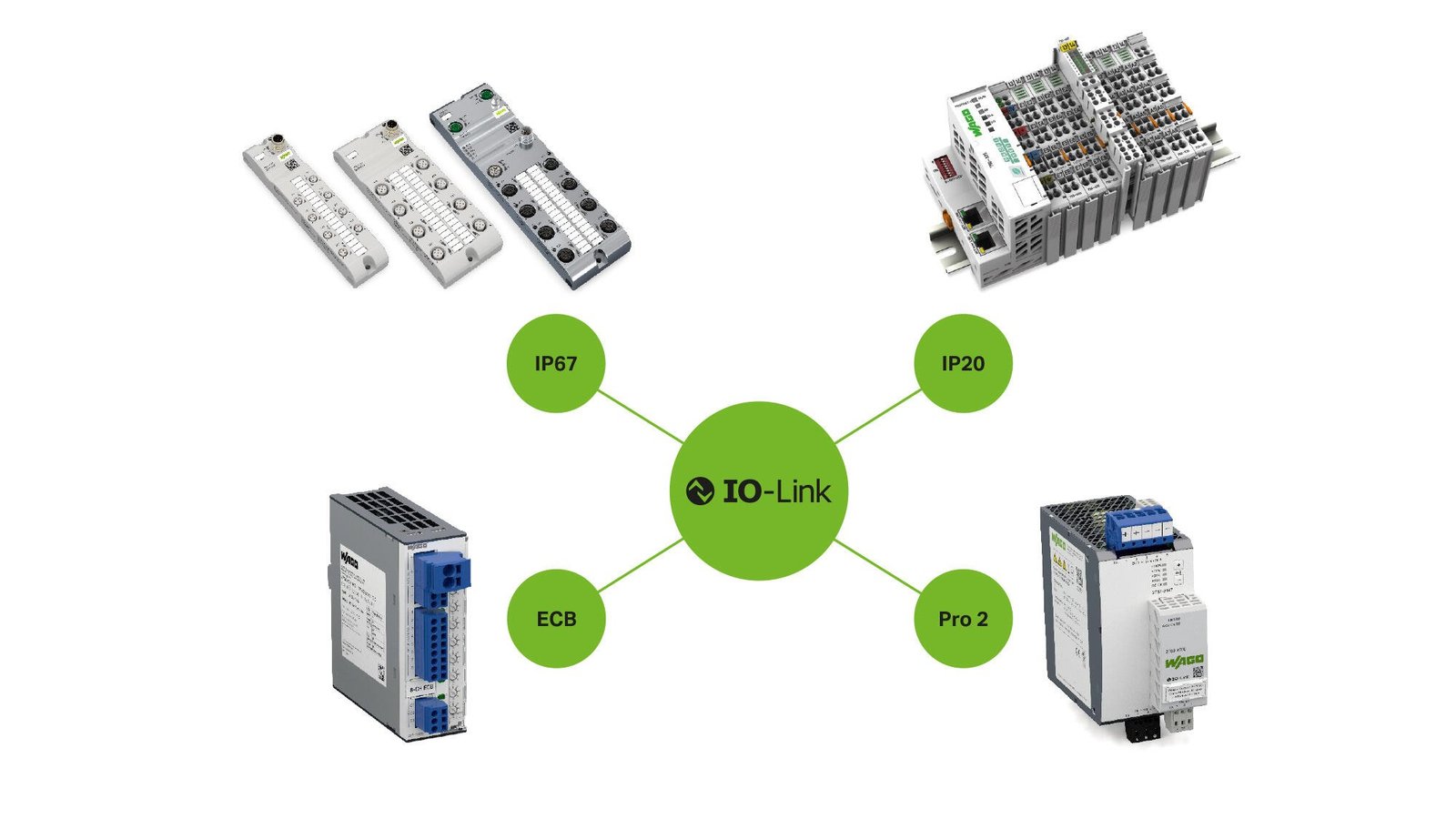

Hệ Thống I/O

Cầu Đấu Dây

Cầu Đấu Dây

Cầu Đấu Dây

Hệ Thống I/O

Rail-Mount Terminal Blocks

Cầu Đấu Dây

Cầu Đấu Dây

Bộ Điều Khiển PLC

Hệ Thống I/O